Szybkie menu

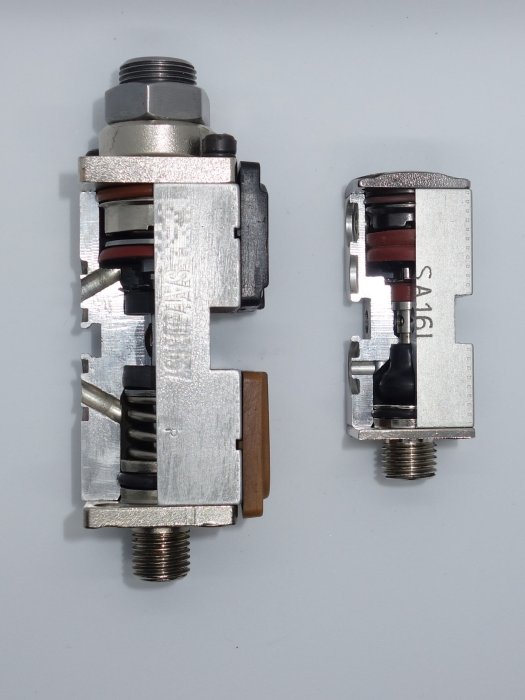

Glue module Nordson

Glue module

The Nordson Solid Blue S glue module is a device used for applying glue in the packaging industry and other industries. The operating principle of this glue module is to heat and dissolve the glue at the appropriate temperature and then apply it to the surface of the material using a nozzle.

The Nordson Solid Blue S glue module is equipped with special nozzles that allow precise and even application of glue on various types of surfaces. Thanks to this glue module, durable and aesthetic connections between materials can be obtained.

In addition, the Nordson Solid Blue S glue module is easy to use and maintain, which makes it a very practical tool in the production process. It can be used for gluing paper, cardboard, cardboard, plastics, metal, wood and other materials.

It is also worth noting that the Nordson Solid Blue S glue module is very efficient and economical, which translates into lower production costs. It is therefore an excellent solution for companies looking for effective and professional glue tools.

The Nordson SureBead glue module is a device that is used to apply glue to various surfaces. This module works by heating the glue to the appropriate temperature and then pumping it through application nozzles to the surface on which it is to be used.

The SureBead system is characterized by precision and control of the amount of glue used, which allows for material savings and avoiding excessive glue application. The Nordson SureBead glue module is a convenient and effective tool for glue application in industry, and its operation is based on the basic principle of heating and applying glue to the surface.

The Nordson Mini Blue II glue module is designed for hot melt glue applications in a variety of applications, such as packaging, food processing, packaging production, etc. It features a compact design that allows for easy installation in a variety of machines and production lines.

The technical specifications of the Nordson Mini Blue II glue module include:

- Operating temperature: 90°C to 220°C

- Heater power: 150W to 300W

- Adhesive flow: 0.2 kg/h to 5.0 kg/h

- Nozzle diameter: 0.2 mm to 2.0 mm

The Mini Blue II glue module is easy to operate and maintain, allowing operators to effectively increase production efficiency. It is also equipped with features such as automatic nozzle cleaning, which prevents clogging and ensures uniform glue application.

With its reliable design and high-quality workmanship, the Nordson Mini Blue II glue module is a popular choice among manufacturers worldwide.

Rebuilding a Nordson SolidBlue S module, a key component of a hot melt application system, can be a complicated process. It requires precision and the right tools. Here is a general guide on how to do it: Step 1: Preparation

- Shut down the unit: Make sure the system is turned off and unplugged.

- Cool down: Allow the unit to cool down to avoid burns.

- Tools: Gather the appropriate tools, such as wrenches, screwdrivers, pliers, and cleaning agents. Step 2: Disassemble the module

- Disconnect the wires: Carefully disconnect all electrical wires and heated hoses from the module.

- Unscrew the screws: Use the appropriate tools to remove the screws that secure the module to the system.

- Remove the module: Carefully remove the module from the unit. Step 3: Cleaning

Remove any adhesive residue: Remove any adhesive residue from the module using an appropriate cleaning agent. You can use special solvents designed for hot melt adhesives.

Cleaning the components: Thoroughly clean all the components of the module, such as nozzles, filters and heating elements.

Step 4: Inspecting and replacing parts

Checking the condition: Thoroughly inspect the condition of all the components of the module. Look for wear, damage or corrosion.

Replacing parts: Replace any damaged or worn parts with new ones. This may include seals, nozzles, filters or heating elements.

Step 5: Assembling the module

Assembling the module: After thoroughly cleaning and replacing parts, reassemble the module.

Fastening the screws: Screw the module back into the system, making sure that all screws are securely tightened.

Connecting the wires: Connect all the electrical cables and heating hoses.

Step 6: Testing

- Starting the system: Turn on the system and allow it to heat up to the appropriate temperature.

- Functional check: Test the module to make sure everything is working properly and there is no adhesive leakage.

Concluding remarks • Safety: Always follow safety rules when working with heating and electrical equipment. • Manufacturer’s instructions: Always follow the manufacturer’s instructions and recommendations for maintenance and rebuilding modules.

If you do not feel comfortable rebuilding the module yourself, it is worth contacting a professional Nordson service who can perform this operation for you.

The Nordson MiniBlue II adhesive module is an advanced device used in hot-melt adhesive application systems. It is designed for precise adhesive dispensing in a variety of industrial applications. Here’s how it works: How does the Nordson MiniBlue II adhesive module work?

- Adhesive heating: o Tank: The hot-melt adhesive is heated in the tank, where it transforms from a solid to a liquid state. o Heating elements: The tank and hoses are equipped with heating elements that keep the adhesive in a liquid state.

Glue transport: o Pump: The liquid glue is transported by the pump to the MiniBlue II glue module. o Heated hoses: The glue flows through the heated hoses, which maintain its temperature at the right level.

Filtration: o Filters: Before reaching the module, the glue passes through filters that remove any impurities, ensuring the glue is clean.

Glue dispensing: o Solenoid valve: The MiniBlue II module is equipped with a solenoid valve that controls the glue flow. The valve opens and closes at very short intervals, allowing for precise glue dispensing.

o Nozzle: The glue is applied through a nozzle that can be adjusted to different application patterns, such as lines, dots or spirals.

- Control: o Control panel: The module is controlled by a control panel that allows you to set parameters such as temperature, pressure and valve opening time. o Sensors: The system can be equipped with sensors monitoring temperature and pressure, which ensures stability and repeatability of the adhesive application. Advantages of the Nordson MiniBlue II module:

• Precision: Accurate adhesive dispensing thanks to the advanced solenoid valve. • Speed: Fast opening and closing of the valve allows for the application of adhesive in very short time intervals. • Energy efficiency: Low energy consumption thanks to efficient heating elements. • Reliability: Robust construction and high-quality components ensure a long service life of the module. • Ease of maintenance: The module is designed to be easy to maintain and replace parts.

Typical applications: • Packaging: Application of adhesive to cartons, boxes and other packaging. • Furniture production: Bonding of furniture elements. • Automotive: Application of adhesive in assembly processes.