Szybkie menu

Valco Melton Filters

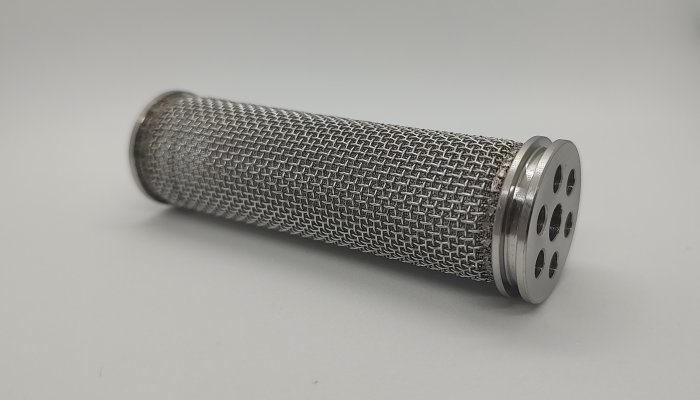

Valco Melton Filter

The Valco Melton glue filter is a part of the device used in the hot melt glue system to filter and clean the glue before it is applied to the surface. Its task is to remove impurities and contaminants that could disrupt the glue application process and the quality of the joint. By using the Valco Melton glue filter, you can ensure more stable and precise operation of the glue machine and better final glue application results.

The Valco Melton filter is an element used in Valco Melton’s dosing and application systems, which is used to eliminate impurities and foreign bodies, mainly from hot melt adhesives, but also from waxes or other precisely dosed substances. The principle of operation of the Valco Melton filter is to pass the fluid through a specially designed mesh or filter cartridge, which stops all particles and impurities, preventing them from passing further into the system.

The Valco Melton filter can be used in various types of applications, such as gluing or dosing fluids in industry. By removing impurities, it allows to maintain high quality of application and protects against damage and failure of equipment.

It is also worth noting that Valco Melton filters are easy to replace and maintain, which makes them a convenient and effective solution for maintaining the proper operation of dosing and application systems.

The Valco Melton gun filter is an element that is designed to stop impurities contained in the supplied paint or other substance. It is an essential part of the paint sprayer, which allows you to maintain high quality and precision of the coating application. With the right Valco Melton gun filter, you can avoid clogging of the nozzle or other elements, which can negatively affect the efficiency and final result of the painting. It is worth checking and replacing the Valco Melton gun filter regularly to maintain optimal working conditions and achieve the best results.

How the Valco Melton Filter Works

Adhesive Input:

Adhesive Input: The liquid hot melt adhesive flows through the heated hoses into the filter. The adhesive may contain contaminants such as material residues, dust, or other solid particles.

Filtration:

Filter Element: The Valco Melton filter contains a special filter element that retains contaminants. This element is made of high temperature and chemical resistant materials, ensuring its durability and effectiveness. Contaminant Removal: As the adhesive flows through the filter element, the contaminants are retained and the clean adhesive continues into the application system.

Adhesive Output:

Cleaned Adhesive:

After passing through the filter, the cleaned adhesive is transported further to the applicator (glue gun), where it is precisely dosed onto the material surface.

Benefits of using the Valco Melton filter

• Improved application quality: Removing contaminants from the adhesive prevents nozzle clogging and ensures consistent adhesive dispensing.

• System protection: The filter protects the pump, hoses and applicators from damage caused by contaminants.

• Extended service life: Regular use of the filter extends the service life of the entire adhesive system, reducing the need for frequent repairs and maintenance.

Filter replacement:

• Regularity: The filter should be checked and replaced regularly according to the manufacturer’s recommendations to ensure its effectiveness.

• Instructions: Replacing the filter is usually simple and can be done according to the equipment’s operating instructions.